What It Costs to Maintain an Outboard Motor?

Outboard motors are the pulse of sea adventure. But beneath the cowling is a precision engine, and as with any high-performance engine, its reliability and longevity depend on care and service. Everyone knows the outboard engines start at a few thousand to over $30,000 for the high-horsepower model. But the ongoing maintenance cost remains unclear, yet it is an equally critical financial decision.

Think about this: a well-maintained outboard can provide thousands of hours of trouble-free operation, adding years, even decades, to its life. On the other hand, skipping maintenance will mean a a costly breakdown, frequently costing more than a replacement engine.

Outboard servicing is not just about preventing failure; it's about optimizing performance, maintaining fuel efficiency, and ultimately, protecting your peace of mind on the water.

The in-depth guide will lift the curtain on the real economics of outboard repair, providing expert insight into the most influential determinants of costs and service rates by engine size and type. Moreover, we will also share smart tips to protect your outboard and wallet.

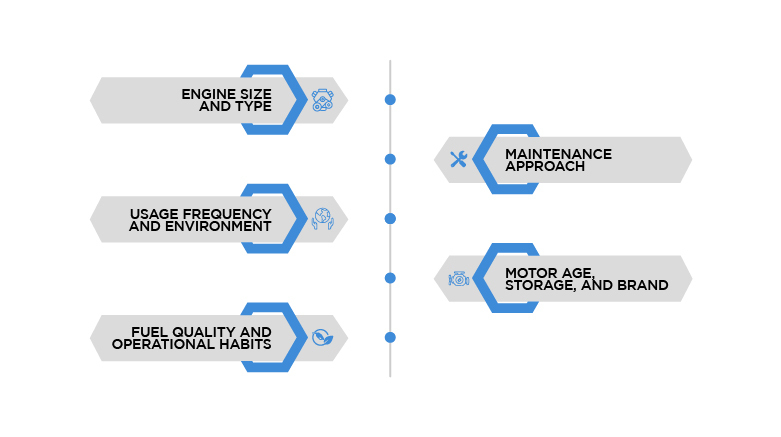

Factors Affecting Outboard Maintenance Costs

Outboard maintenance cost is a dynamic figure influenced by several critical variables. Each plays a significant role in the overall expenses.

1. Engine Size and Type (2-Stroke vs. 4-Stroke)

Larger engines naturally incur higher costs due to their complex systems, increased oil/fuel capacity, and wear-prone components. For example, the maintenance cost of a 300HP four-stroke with digital throttle control, hydraulic steering, and multi-bank fuel system will cost more to service than a 25HP 2-stroke with manual tilt and carburetion.

- 2-stroke engines are known for their simplicity and lighter weight. Their maintenance is less expensive in the short term, but they burn oil and often require more frequent top-end rebuilds.

- 4-stroke engines require frequent oil changes, filter replacements, and valve clearance. Due to complex mechanics, they might have higher upfront and maintenance service costs, but the engine provides better fuel economy, quieter operation, and longer service intervals.

2. Usage Frequency and Environment (Saltwater vs. Freshwater)

How often you run your engine and where you operate profoundly impact wear and tear. More hours on the water mean more frequent fluid changes, impeller replacements, and inspections of wear components. A motor logging hundreds of hours annually will cost more than one used a dozen times.

- Saltwater Operation: The corrosive nature of saltwater is the outboard’s greatest enemy. The environment necessitates flushing after every use, more frequent anode replacement, and more care for corrosion on electrical connections and fasteners. Due to accelerated wear, saltwater leads to higher long-term maintenance costs.

- Freshwater Operation: The less corrosive, freshwater use still requires regular maintenance. Sediment and organic matter can impact cooling systems and fuel filters, though the maintenance schedule can generally be slightly less rigorous than for saltwater-exposed engines.

3. Fuel Quality and Operational Habits

Fuel quality directly impacts combustion, injector health, and internal corrosion. Modern outboards are highly sensitive to fuel quality. If not properly managed with stabilizers, ethanol-blended fuels can lead to phase separation, water contamination, and degradation of fuel lines and components. It’s best to use non-ethanol fuel where available or consistently use a high-quality fuel stabilizer.

Consistent wide-open throttle operation stresses an engine, potentially accelerating wear on internal components. Conversely, prolonged idling can lead to carbon buildup. The best method is to run the engine at optimal RPMs and allow a proper warm-up and cool-down period, significantly extending the component life.

4. Maintenance Approach (DIY vs. Professional Service)

Many seasoned boaters can easily handle some maintenance tasks. They have the tools and skill set to save them on labor costs. While DIY maintenance saves on hourly rates, it demands initial investment in tools and your valuable time.

Certified marine technicians ensure the work is done correctly and often back their work with a warranty. Professional service can be expensive, but it provides peace of mind, especially for complex diagnostics or repairs that require specialized equipment.

5. Motor Age, Storage, and Brand

These overarching factors play a crucial role in the long-term maintenance cost.

- Motor Age: Older engines may require frequent attention due to component wear and the eventual need for major overhauls. Parts of older models are sometimes harder to source or more expensive.

- Storage: Proper winterization and storage prevent damage from freezing, corrosion, and fuel degradation. Neglecting storage can lead to costly repairs in the spring.

- Brand: The quality varies across brands; some manufacturers might have slightly higher parts costs or require specialized diagnostic tools only available to their certified service centers.

Outboard Maintenance Cost by Engine Size & Type

Small Engines (2–25 HP)

DIY Cost: $50-$100

Professional Service Cost: $110-$250

These engines are the most economical to maintain: smaller fluid capacities, fewer cylinders, and simple designs, leading to lower oil costs, fuel filters, and spark plugs. Impeller replacement is typically on the lower side.

Mid-Size Engines (30–115 HP)

DIY Annual Cost: $100-$200

Professional Service Cost: $250-$400

The mid-sized engine often hit the sweet spot for many boaters. These engines balance power with reasonable maintenance demands. Costs for fluids and common wear parts will be higher than for a smaller engine. While many basic tasks are DIY friendly, the diagnosis and fixing of uncommon issues require professional attention.

Large Engines (150–300+ HP)

DIY Annual Cost: $175-$250

Professional Service Cost: $520- $800+

The powerful outboards have higher maintenance expenses. They demand more oil, larger and more expensive fuel filters, and potentially more specialized components.

The advanced engines have sophisticated electronic control units, hydraulic steering, and an intricate fuel injection system that requires professional services. Given their complexity and higher loads, professional services are often recommended for comprehensive inspections and diagnostics.

2-Stroke vs. 4-Stroke Engines

Modern 4-stroke engines have become the dominant force; understanding their maintenance cost difference is still relevant.

- 2-Stroke engines have fewer parts and no engine oil changes, as oil is mixed with fuel. However, they consume 2-stroke oil, which is an ongoing cost. Older carbureted and early EFI 2-strokes can also be prone to carbon buildup if not decarbonized regularly.

- 4-Stroke engines require regular engine oil and filter changes, which are a consistent cost. Moreover, they often have timing belt or chain issues that require inspection or replacement at higher hours, adding to long-term costs. The type of engines generally offers better fuel efficiency, which can offset maintenance expenses over time.

Average Outboard Maintenance Cost by Service Type

A tangible sense of cost is not easy to provide, so let’s break down typical expenditures for common services. The figures represent averages and can fluctuate based on region, service providers, specific engine providers, and the cost of quality parts.

|

Maintenance Task |

DIY Cost (USD) |

Professional Cost (USD) |

Notes |

|

Oil & Oil Filter Change |

$30 – $60 |

$80 – $150 |

DIY saves labor costs; must dispose of oil properly. |

|

Lower Unit Gear Oil Replacement |

$15 – $30 |

$60 – $100 |

Easy for DIYers with a drain/fill pump tool |

|

Spark Plug Replacement |

$10 – $25 |

$40 – $100 |

Basic DIY task; proper gapping is crucial. |

|

Water Pump Impeller Replacement |

$40 – $60 |

$120 – $250 |

DIY requires mechanical skill and service manual. |

|

Fuel Filter & System Cleaning |

$10 – 40$ |

$120 – $400 |

DIY involves filter replacement; a professional may include injector service |

|

Full 100-Hour Service |

$160 – $250 |

$200 – $300 |

Comprehensive service including fluids, filters, inspections, etc. |

|

Winterization/Storage Prep |

$50 – $300 |

$145– $500 |

Essential for protecting the engine during the off-season |

|

Anode (Zinc) Replacement |

$20 – $40 |

20$ – 50$ |

Critical for corrosion protection, especially in saltwater |

Seasonal & Annual Maintenance Costs

Outboard motors require routine care throughout the year to ensure reliability, longevity, and peak performance. While some maintenance tasks are seasonal, depending on usage and climate, others are manual must-dos for which every boat owner should budget.

Spring Commissioning

Before the boating season begins, most owners invest in a spring tune-up. It is an essential pre-season task.

- Replacing spark plugs

- Inspecting fuel lines, hoses, and clamps for signs of cracking and degradation

- Checking the water pump impeller and replacing if required

- Changing engine oil, filter, and lower unit gearcase lubricant

- Propeller inspection for damage

The maintenance task cost is $110-$280 when professionally performed, depending on the size and brand of your motor.

End-of-Season Winterization

Winterizing your outboard is essential if you live in a region with freezing temperatures. It is a critical preventive measure to save the engine during the brutal weather.

The process of winterization involves:

- Stabilizing fuel to prevent ethanol-related issues and fuel degradation

- Engine fogging includes fogging oil into the cylinders to prevent rust and corrosion

- Ensure all the water is drained to prevent freezing damage to the block and lower unit

- Lubrication, all zerk fittings, and moving parts to prevent seizing

- Battery management, removing and storing it in a cool, dry place

Professional winterization ranges from $50 to $500, but skipping it can lead to far more costly repairs. Skipping this process can lead to cracked blocks, damaged fuel injectors, and corroded powerhead internals, costing thousands of dollars in repairs.

Annual/100 Hours Service

Most manufacturers recommend a comprehensive service every 100 hours or once a year, whichever comes first. The full service extends beyond basic checks and involves:

- Full engine oil and filter changes

- Water pump inspection or replacement

- Thermostat inspection and testing/replacement

- Thorough fuel system service, including primary and secondary filter replacement and inspection of fuel lines and VST (Vapor Separator Tank).

- Comprehensive corrosion inspection, anode replacement, and corrosion inhibitors application.

- Inspection of spark plugs, belts, hoses, and electrical connections

- Lower unit gear oil replacement and seal inspection

Depending on motor horsepower and service provider, this can cost $160 to $300 annually. The routine and comprehensive maintenance ensure long-term reliability and retain maximum resale value.

Long-Term Cost: Replacement Parts & Wear

Beyond routine maintenance, outboards require occasional replacement of components due to wear, age, and accidental damage.

- Propeller: Dings, bends, or missing blades can lead to vibrations and reduced performance. Moreover, it puts extra strain on the engine, accelerating parts wear and repair requirements.

- Anodes (Zinc): It is a sacrificial part that protects you from galvanic corrosion, especially in saltwater. Sacrificial anode degrade over time and must be replaced annually or when they can no longer perform their tasks.

- Trim and Tilt System: Hydraulic leaks, faulty motors, or solenoid failures can affect the engine’s maneuverability.

- Steering Systems: Whether the system has mechanical cables or hydraulic lines, they will wear over time. So, if you are sensing stiff steering, it often indicates a binding cable or degraded hydraulic fluid

- Electrical System Components: Corrosion is a silent killer. Worn wire harnesses, faulty sensors, igniters, or charging components like stators and rectifiers can cause intermittent issues or complete breakdown.

- Lower Unit Seals & Bearings: The critical components maintain the integrity of your gearcase, preventing water intrusion into the gear oil. Over time, seals harden and bearings wear, which can lead to water damage. You might have to rebuild or replace the lower unit if left unattended.

Hidden Essentials & How to Save on Maintenance

Sometimes, the most significant expenses are those not immediately apparent. Catching them early can extend the life of your outboard engine.

- Neglecting the Fuel System: Poor fuel quality is a leading cause of expensive repairs. It often leads to fuel injector cleaning or replacement, fuel pump issues, and carburetor rebuilds. This can easily turn into hundreds or even thousands of dollars.

- Corrosion: It is the biggest problem in saltwater conditions. Corrosion prevention is crucial, because if let unchecked it can seize bolts, damage electrical connections, and compromise structural integrity. It leads to complex and costly repairs.

- Ignoring Small Issues: A minor rattle, a slight drop in RPMs, or a subtle change in sound can lead to something big. If ignored, it can escalate into catastrophic failure.

- Improper Storage: Many beginners and even seasoned boaters do not emphasize proper storage. Improper winterization can lead to cracked blocks from freezing water, corroded cylinders, and damaged fuel systems.

- Lack of a Service Manual: DIYing outboard maintenance without a service manual is dangerous. A proper manual highlights the specific requirements and methods for the particular outboard engine. Careless DIY outboard maintenance can cause more damage in the long run.

How to Save on Maintenance Costs?

Outboard maintenance cost is inevitable, but implementing smart habits can significantly improve your engine’s performance, extend its life, and protect your budget.

- Strictly adhere to the manufacturer’s schedule. Preventive maintenance is always cheaper than reactive repairs.

- Always flush your engine after every use in saltwater. The simple action is your best defense against corrosion, as it prevents salt crystals from building up in the cooling passages.

- Learn basic DIY maintenance tasks like oil changes, gear lube replacement, spark plug swaps, and more. It can save significant labor costs over the years.

- Before and after each trip, dedicate a few minutes to a quick visual inspection for leaks, loose connections, unusual wear, and foreign debris around the propeller.

- Shop around for parts. If new parts are out of budget, opt for remanufactured marine parts, OEM-quality aftermarket outboard parts, or used outboard parts from quality retailers.

- Don’t let a small problem become a major breakdown; address every issue promptly. Ignoring these early warnings is the direct path to a major breakdown and higher repair bills.

Learn: Top Benefits of Buying Remanufactured Mariner Parts

The Bottom Line

Maintaining an outboard motor should not be considered an expense but a critical investment. It safeguards your marine asset, optimizes its performance, and ensures countless hours of trouble-free enjoyment on the water. Engine size, type, working conditions, frequency of usage, age, and brand of the motor influence the outboard maintenance cost.

The best practice is to adhere to manufacturer-recommended service intervals, perform diligent preventive tasks, and address every issue quickly, which minimizes the likelihood of unexpected repairs.

Ultimately, a well-maintained outboard motor isn’t just about preserving mechanical integrity; it’s about preserving your passion for boating. So, invest wisely in your motor’s health, and it will power countless adventures for years.

So, whether you are DIYing the outboard maintenance and seeking a professional’s assistance, OBParts can stock you with the best New, OEM-Quality Aftermarket, and Remanufactured Outboard engine parts to keep your engine running strong.

Posted by Brian Whiteside