Guide to Jet Outboards - Performance, Efficiency, & Selection Tips

If you’re even thinking about jet outboards, you’re probably tired of scraping props on river bottoms or getting stuck in ankle-deep water like it’s your full-time job. Jet outboards aren’t just another trendy upgrade; they work great in shallow water boating, period. But before you throw cash at the first engine with “jet” in the name, it’s worth knowing what you're really getting into.

They have quirks, require some trade-offs, and knowing how they actually work could save you from making an expensive mistake. That’s exactly what this post is about. Let’s get into it.

What Is a Jet Outboard?

A jet outboard is an outboard motor that uses a jet propulsion system instead of a traditional propeller. It draws water into a pump, accelerates it with an impeller, and shoots it out of a nozzle to push the boat forward.

Here’s what sets them apart:

- No exposed propeller: Great for safety and navigating weed-heavy or debris-filled water.

- Shallow-water navigation: Jet motors need only inches of water to operate.

- Internal jet system: Minimizes drag and improves handling in tight spaces.

Jet drive outboards are commonly used in shallow rivers, creeks, and whitewater areas where propeller-driven boats would struggle or risk damage.

How Jet Outboards Work?

The Basic Principle: Water In, Water Out

At the core of a jet outboard motor is the idea of pulling in water, pressurizing it, and shooting it out with high force to create thrust. This process eliminates the need for a spinning propeller and instead relies on a powerful stream of water to move the boat forward or backward.

Step 1: Water Intake

The journey begins at the intake grate, located on the bottom of the motor (and usually the boat’s transom area). This grate protects the jet pump system from large debris like rocks, weeds, or sticks. As the boat idles or moves forward, water is sucked up through this intake by a rapidly spinning impeller.

Step 2: Impeller Acceleration

Inside the housing, the impeller, a heavy-duty metal or composite fan, spins at extremely high speeds. This spinning action pulls in large amounts of water and pressurizes it within a tight chamber.

Unlike propellers that push water back in open space, impellers spin inside a close-fitting housing, which forces the water to compress. This compression dramatically increases water speed and pressure.

Step 3: Nozzle Thrust and Directional Steering

Once the water is pressurized, it is forced out of a nozzle at the rear of the engine. This nozzle works like a firehose, creating a narrow jet stream of high-velocity water that propels the boat forward.

But how do you steer? That’s where the steering nozzle comes in. It swivels left or right based on your steering input, directing the flow of water and changing the direction of the boat. Some systems also feature a reverse bucket that drops down to redirect the water flow forward; this allows the boat to go backward without a reverse gear.

Forward and Reverse Motion

In most jet drive outboards, forward motion happens when the water jet is allowed to shoot straight out the back of the motor. For the reverse, a deflector bucket (or reverse gate) is lowered into the stream. It redirects the water under the boat, pushing it in the opposite direction. This reverse function allows for quick stops, tight maneuvering, and excellent control even in close quarters.

The Pros and Cons of Owning a Jet Boat

| PROS | CONS |

| Operate in Very Shallow Water, Only need 4–6 inches to run. | Reduced Fuel Efficiency at Cruise Speeds |

| Eliminates prop strike risk in rocky, debris-filled, or vegetative waters, ideal for rivers and sandbars. | Power Loss in Jet Conversion (Approx. 30%) |

| Internal jet propulsion system reduces injury risks in rescue zones or recreational areas. | Susceptible to Intake Clogging |

| Jet drive systems offer instant thrust response and a tighter turning radius compared to prop-driven systems. | Lower Performance in Deep, Open Water Conditions |

| Preferred by anglers for accessing remote fishing spots where conventional boats can't reach. | |

| Minimal underwater footprint allows navigation over obstacles and through weed-choked or silty waterways. |

Choosing the Best Boat Material for Jet Outboards

The right jet outboard motor isn’t just about horsepower; it’s about matching your engine to the hull design, water type, payload, and intended use.

1. Engine Horsepower Requirements

Jet outboards typically lose around 30% of usable power compared to prop-driven motors due to jet pump inefficiencies. If your boat needs a 60HP prop motor, you'll need at least an 80HP jet outboard to get similar performance. Always upsize accordingly.

2. Boat Type and Weight

Jet outboards work best on lightweight, flat-bottom boats that sit high in the water. Heavier boats or those with deep-V hulls may struggle to plane and handle efficiently with jet propulsion. Know your boat’s specs before deciding.

3. Water Conditions You Navigate

If you're operating in shallow rivers, rocky streams, or backwater flats, a jet outboard is ideal. But if you often boat in deep lakes, open bays, or saltwater, a prop outboard may perform better and more efficiently in those settings.

4. Maintenance Capability

Jet outboards require regular checks on the impeller, wear ring, and intake grate. If you’re not comfortable doing basic maintenance or don't have easy access to service centers, consider this when choosing your power setup.

5. Factory Jet vs Jet Conversion Kit

You can either buy a factory-built jet outboard or convert a prop outboard using a jet conversion lower unit. Factory jets are better optimized for efficiency and durability, while conversions may be more cost-effective but less refined.

Jet Outboard Conversion vs Buying a Jet Engine

Combining the correct outboard power and boat design is the “secret” of successfully using an outboard jet to run in shallow water. There are two options for getting to these fishing hot spots that others can't reach:

Buy a jet outboard or convert an existing motor. Most people don’t know this, but many outboards can be converted to jet propulsion for a few thousand dollars, depending on their size.

This conversion, along with the proper boat, can allow a boat to run in just a couple of inches of water — and potentially scoot over short sections of land (not recommended), if such an action is required.

These two pieces of information will assist you in selecting the best combination for your needs, thereby giving you the advantages of outboard power for shallow water use.

A flat bottom boat runs shallower than a vee bottom, but slides on the turns more.

A vee bottom splits off air bubbles before they reach the jet intake. A flat bottom carries bubbles straight back.

A slight V of 6-10 degrees dead rise will enhance jet boat handling.

Why Deep Vee Hulls and Keels Are Not Ideal for Jet Outboards?

Deep vee is not desirable for the Outboard Jet, not just because of increased draft and drag, but because the Outboard Jet needs a flat apron of water about 10” wide, leaving the hull on which to set the leading edge of the jet intake, to minimize air intake and frontal drag.

The dead rise should be fairly constant and not increase to a deep forefoot at the bow.

Jet Tunnel Design for Jet Drive Boats

A deep forefoot can cause spinout on a sharp turn. Keels can be a problem, introducing air into the jet intake. Center keels vary in size and may introduce air.

If this is suspected, the keel should be removed 2-3 feet forward of the transom. Other keel arrangements that tend to funnel air to the jet intake should be avoided. The chine of the boat, where the sides meet the bottom, should be sharp.

Round chimes tend to suck the boat down in the water and cause drag. A properly designed tunnel, combined with a slight V-bottom hull, can greatly enhance jet boat performance.

It should raise the motor 2-3 inches and place the heel of the jet intake flush or slightly above the bottom of the boat. A jet tunnel doesn’t work well with a flat-bottom boat due to air ingestion. It’s imperative that the hull is designed correctly with the tunnel for the boat to operate properly.

The tunnel needs to be just large enough to feed the jet drive its water requirements. A tunnel that is longer, wider or deeper than necessary wastes power in lifting excess water, tends to suck the stern down when planing and sits deeper in the water at rest due to lost buoyancy. The top of the tunnel width should be about 1 ¾ times the width of the jet drive water intake.

The tunnel length doesn’t have to be longer than about 2 ½ times the water intake width.

Using Jet Outboards on Pontoon Boats

Pontoon boats don’t provide a defined height apron of water ahead of the jet intake. The water level between the pontoons varies with speed and load carried.

It’s necessary to build an inclined plane ahead of the jet intake attached to the motor mount, about 16” wide, inclined at about 15 degrees with the leading edge above water level, fully loaded at rest, trailing edge lined up with the leading edge of the jet intake.

Jet Outboard Horsepower Loss and Performance Factors

Jet Pump engines are considerably less expensive, since they don’t have expensive stainless steel shafts, gears, and props, but there’s a price to pay: usable power.

Take, for example, the Yamaha F150. It uses a 2.7L in-line four-cylinder four-stroke to make 150 hp, with a prop.

Equipped with a jet drive, however, Yamaha puts something else on it: a cowling with the number 105, because that’s how much power it generates due to a jet’s relative inefficiency. It goes down the line: F115 (80 hp), F90 (65 hp), F60 (40 hp) and F40 (30 hp).

The other major engine brands experience a similar reduction in thrust, and the selection is limited. Mercury has five but in the narrowest range of horsepower, with models producing 80, 65, 40, 35, and 25 hp.

There is about a 30% power loss when converting to jet drive. A suitable outboard jet boat carrying an average load will provide about 80% of propeller speeds.

How Much Horsepower You Need for Jet Outboard Boats

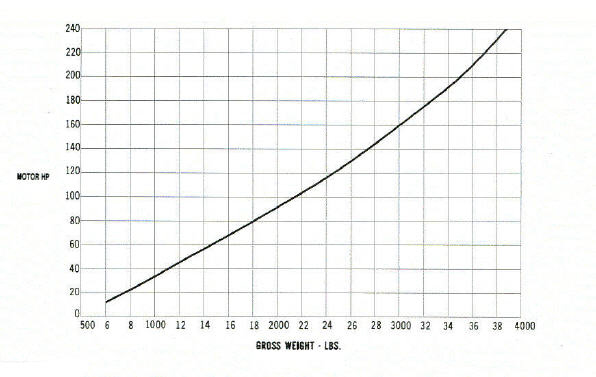

It’s important to decide what load you want to carry how many people, gear, fuel, etc. and add the weight of the boat, motor and battery. Look up this gross weight on the chart below to determine the minimum HP you need. The chart HP is power head horsepower. It’s important that the boat motor combination plane the boat quickly. Planning would normally be in the mid-20 MPH range and up. This is necessary for optimum jet performance and shallow water running. At low RPM, when the boat is not planing, you would need about 12 inches of clearance between the bottom of the jet and river bed to maneuver.

It’s important that the boat motor combination plane the boat quickly. Planning would normally be in the mid-20 MPH range and up. This is necessary for optimum jet performance and shallow water running. At low RPM, when the boat is not planing, you would need about 12 inches of clearance between the bottom of the jet and river bed to maneuver.

Jet Boat Cavitation, Planing, and Handling Issues

Poor performance will show up in a jet boat, taking a long time to get up on a plane, breaking loose early in cornering, and causing cavitation.

The advantages of Outboard Jet boat include maximum space inside the boat while still having the ability to operate in less than 6” of water, relative ease of cleaning out a clogged pump, and adjustment for wear on the impeller and intake liner. So select a suitable boat with sufficient HP to handle your total weight, then enjoy fishing and hunting in areas you couldn’t reach before.

Yamaha has a company division that makes jets for personal watercraft, but it’s interesting that they, along with Mercury, Honda, and Tohatsu, source their jet drives from Outboard Jets, which has been making them since 1960 and is the king of jet outboard components.

Almost every jet drive pump on the water today, no matter what brand motor, is made by a single company: Outboard Jets out of San Leandro, California. The company was started in 1960 by Dick Stallman, who worked closely with the Wooldridge family to form the product that you know today as the jet drive. Today, Outboard Jets builds over 80 different models to fit 6 of the top-name outboard manufacturers in the marine industry.

Jet drives aren’t compatible with every type of waterway. Mud, for instance, is a jet killer, so a better solution for going into muddy areas is an air-cooled motor such as a propped Mud Buddy. Jets work best on hard bottoms such as rocky riverbeds.

They work OK over sand, but it, like small rocks, tends to abrade parts such as the impeller and the wear ring that surrounds the impeller. If the impeller doesn’t fit tightly within the wear ring, power is lost, like with a worn ring on a piston in a combustion engine.

The impeller can also get dinged up, which costs power, but carefully filing rough spots can bring it back to life. The wear ring is a sacrificial part that costs about $50 to replace when it gets grooved.

Final Thoughts on Choosing a Jet Outboard

The use of outboard jets is definitely on the rise, and we will be seeing a lot more of them on the rivers in the years to come. If you are an angler who is thinking about purchasing an outboard jet, these are some great things to keep in mind when looking.

Looking for a JET OUTBOARD ENGINE to replace your PROP OUTBOARD ENGINE?

For more information on outboard motors, contact us today!

Posted by Dr. Johnny Fever