Performance vs OEM Marine Clutches – Materials, Stages & Drivability Explained

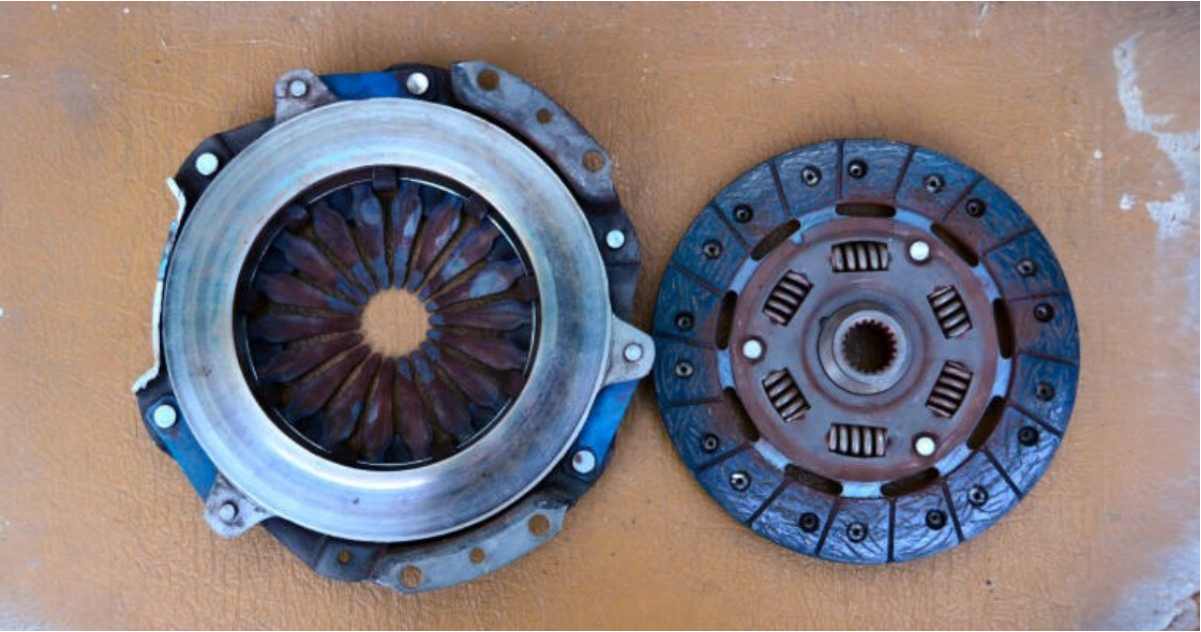

When it comes to boat drivetrains, the clutch isn’t just a part but a quiet intermediary that connects your engine to the propeller, and keeps everything smooth and safe out on the water. Performance clutches may feel jerky when maneuvering into reverse at the dock, something OEM clutches usually handle more smoothly.

OEM clutches, they’re good, built to handle “normal” loads, casual cruising, predictable comfort. But the second you’re pushing that drivetrain harder, be it higher horsepower builds, performance prop upgrades, or you just love throttle pulls, OEM clutches are not suitable. And that’s where performance clutches come into play.

In this post, we will make a clear difference between the two clutches in their materials, longevity, torque handling, and corrosion resistance. Let’s get started.

What is an OEM Clutch?

An OEM clutch means the same company that built your boat or engine also built the clutch. It’s not just close in design, it’s made to the exact specs your machine needs. That’s why it fits right, runs smoothly, and lasts longer without extra hassle. You're not relying on assumptions; you're getting parts tailor-made for your vessel.

For example, a Yamaha OEM clutch plate kit delivers precise spline engagement, rugged construction, and corrosion-resistant materials to handle saltwater, UV exposure, and marine environments.

OEM clutches mean you can expect seamless installation, near-perfect compatibility, and design-tested performance. These components are held to the manufacturer's standards, giving you consistency and confidence that aftermarket options may not match.

What is a Performance Clutch?

A performance clutch is built for people who push their vehicles harder than normal. It’s not your regular OEM replacement but a stronger aftermarket unit. The design uses durable parts, rust-resistant metals, and friction surfaces reinforced to last longer. It’s also made to handle more torque, meaning it can deal with heavy loads and rough driving without slipping. Drivers who face tough conditions rely on it because it gives more control and stability compared to a standard clutch.

Performance clutches are MADE for specific enhancements, like smoother engagement under heavy thrust, better heat dissipation, or rapid response during tight manoeuvring. You’ll find them in applications such as high-speed yachts, tugboats, fishing vessels, and racing boats, where rapid engagement or frequent shifting demands extra robustness.

Rather than just “fit and leave,” they prioritize resilience designed to offer dependable control when you’re throttling hard or operating in saltwater, heavy-duty environments.

Key Differences Between Performance Clutch and OEM Clutch

The following distinctions make it easier to decide which clutch fits your driving needs, daily comfort, or peak performance.

1. Friction Materials: Organic vs Kevlar vs Cerametallic vs Sintered

When you’re steering a boat, docking, cruising, or powering through chop, the friction material in your marine clutch dictates how smoothly that power transitions from engine to propeller. Here are the four main options:

Organic

This is the go-to material for stock marine clutches. Built from phenolic resins, rubber, and fibrous fillers, organic plates offer engagingly smooth, comfortable transitions and are forgiving on both clutch and flywheel surfaces. They don’t demand much attention and require minimal break-in. That said, in prolonged high-heat scenarios like frequent heavy loads, they can fade, meaning their gripping ability diminishes when things get hot.

Kevlar

Kevlar-infused friction discs bring serious durability and heat resilience. Drivers (or skippers) who push their vessels a bit harder appreciate their longevity; Kevlar can last two to three times longer than organic materials. Engagement is still relatively smooth, but it comes with a longer break-in window and slightly higher pedal (or lever) effort.

Cerametallic

Cerametallic blends merge ceramic and metallic compounds (think copper-based mixes) to deliver greater torque capacity and superior heat tolerance. They bite more firmly than organic materials, yet typically feel more controlled than pure ceramic clutches. Perfect for high-load or fast-response marine applications, they’re still mild enough for frequent use, just expect slightly firmer engagement and a shorter break-in.

Sintered Metallic

In marine environments, these are the unshakable workhorses. Made by fusing metal powders under high heat and pressure, sintered discs tackle saltwater exposure, extreme loads, and high heat without adhesive failure. They’re ideal in demanding marine applications, think large yachts or industrial vessels, where reliability under harsh conditions is non-negotiable

2. Disc Design: Full-Face vs Puck (3/4/6-puck), Sprung vs Rigid Hubs

The disc’s design directly defines engagement feel, durability, and how forgiving the connection is between your engine and propeller.

| Design Type | Overview | How It Feels / Works | Best For |

| Full-Face Disc (Organic) | A single, continuous ring of friction material, common in OEM and smoother setups. | Smooth, quiet engagement with gentle modulation, very friendly to operators. | Everyday marine use, seamless docking, mild duty |

| Puck-Style Disc (3/4/6 Puck) | Friction material arranged in discrete 'pucks' rather than a full circle. Often lighter. | More aggressive, “grabby” engagement; faster response and lighter; can feel abrupt and noisier. | Racing, high-performance marine vessels with rapid shifts |

| Sprung Hub | Incorporates springs between the hub and the friction disc. | Dampens engagement shock, results in smoother, more progressive clutch action. | Marine use requires smoother starts and drivetrain protection |

| Rigid (Unsprung) Hub | Solid, direct hub with no cushioning mechanism. | Engages almost instantly, very direct, but can transfer harsh shock and noise to the drivetrain. | Strict race or heavy-duty performance marine environments |

3. Pressure Plate & Clamp Load

The pressure plate is the core component responsible for

- clamping the clutch disc against the flywheel

- creating the friction connection that transfers power from the engine to the propeller.

The force applied here is known as the clamp load. Higher clamp load increases torque capacity, but also typically raises the effort required to engage or disengage the clutch, think heavier pull or lever resistance

Most clutches used today, even in high-performance marine engines, run on a diaphragm-style pressure plate. The setup uses a cone-shaped spring (Belleville spring) to create a clamping force. When you press the clutch pedal, the diaphragm flexes to release the disc. It offers efficient pressure delivery and relatively moderate user effort.

To boost clamp load, manufacturers may:

- Adjust the pivot or geometry of the diaphragm spring to increase leverage.

- A stronger or thicker diaphragm spring will elevate the lamp force. It also maintains engagement smoothness, even under demanding torque loads.

Clamp load can be pushed higher for better torque holding and a stronger clutch lock. Still, that comes at the cost of extra work for the operator. Anyone running a boat where slow and steady control matters should think about how much effort feels right for them before making that choice.

When choosing between OEM and aftermarket marine parts, knowing your boat’s torque profile and usage patterns helps ensure you pick the clutch version that aligns with your long-term build.

4. Flywheel Strategy: Dual-Mass (DMF) vs Single-Mass (SMF)

The flywheel plays a critical role in smoothing out engine torque pulses and stabilizing drivetrain performance. Two main designs exist:

Dual-Mass Flywheel (DMF)

In a DMF, you’ll see two linked masses. The first sits on the crankshaft, and the second fits into the clutch. Springs or dampers hold both in place as a team. Their job is simple: soak up engine vibrations before they reach the gearbox. The result is softer clutch action and better protection for the transmission system.

Why does it matter for marine use? By isolating thrust pulses and vibration, DMFs help maintain quiet operation and protect sensitive components in boats that demand smooth power transitions.

Single-Mass Flywheel (SMF)

An SMF is a solid, one-piece disc bolted directly to the crankshaft. It lacks internal damping, resulting in direct power transfer, quicker engagement, and easier resurfacing when worn.

Why do some marine operators like it? SMFs offer responsiveness and lower cost, ideal if sharp engagement and easy maintenance are priorities.

5. Torque Capacity, Heat & Fade: How to Match Your Build

A clutch needs to hold the engine’s torque firmly so it doesn’t slip. Stock OEM clutches are fine for factory engines, but once an engine is tuned or pushed harder, they start to fall short. That’s where performance clutches step in. These are built to take on higher torque loads and keep power flowing without interruption.

Performance marine clutches can handle 40–60% more torque than OEM options.

Heat is another big test. Under stress, clutches can lose grip when temperatures rise. OEM clutches, usually made with organic materials, struggle in those moments. Performance clutches use stronger compounds such as ceramic or Kevlar. They handle extreme heat far better and keep performance steady without fading. Some are tested up to 415 ft-lbs of torque, which is a massive jump, around 64% higher than standard OEM ratings.

Size your clutch for torque, and prioritize designs that manage heat to avoid performance drop-off.

6. Drivability: Pedal Effort, Engagement, Chatter & NVH

Pedal Effort

An OEM clutch feels lighter under the foot, which makes daily boating more comfortable. Long cruises or docking don’t wear you out as much since the pedal takes less effort.

Performance clutches often require increased pedal effort. This is due to stronger diaphragm springs and higher clamp loads. While this design enhances torque capacity, it can lead to increased fatigue during prolonged use.

Engagement Feel

An OEM clutch brings steady engagement. Casual boaters often like how it eases power into motion. The slow shift lowers the chance of stalling, creating comfort through smoother handling.

Performance clutches behave differently. The bite can come suddenly, more so when paired with solid flywheels or tougher friction material. That quick response gives strong power transfer, perfect for high-demand boating, yet sometimes tricky for relaxed cruising.

Clutch Chatter

An OEM clutch usually runs smoothly because its parts are balanced, and the flywheel design keeps things dampened. The result is a quiet drive that feels steady and adds comfort during boating.

Performance clutches change the experience. Because of solid flywheels and stronger friction materials, chatter often appears. Engagement brings small shakes or vibrations. Racers usually accept this trade-off, but someone boating for fun may not find it pleasant.

NVH (Noise, Vibration, Harshness)

In OEM clutch is designed to minimize NVH, providing a quiet and comfortable ride. This is achieved through the use of dual-mass flywheels and dampened components that absorb vibrations and reduce noise.

A performance clutch can handle more torque than stock ones, yet it changes the driving feel. Noise, vibration, and harshness often rise because these clutches usually lack damping features. Materials built for strength also pass on more vibration. Comfort takes a hit, especially on longer drives.

7. Reliability, Warranty, and Serviceability

| Aspect | Performance Marine Clutches | OEM Marine Clutches |

| Reliability | High-torque, high-stress applications may experience increased wear under standard usage. | Engineered for durability and longevity in standard marine operations; generally more reliable for everyday use. |

| Warranty Coverage | Limited warranties ranging from 6 months to 12 months, often with specific conditions. | Often comes with extended warranties, sometimes up to 3 years or unlimited miles, reflecting confidence in long-term reliability. |

| Serviceability | May require specialized knowledge and tools for maintenance; some components may not be easily serviceable or replaceable. | Designed for ease of maintenance with readily available parts and support from authorized service centers. |

8. Cost & Complexity: Performance vs. OEM Marine Clutches

Performance clutches are made to handle heavy torque loads, which is why they’re trusted in racing and tough driving conditions. They don’t come cheap. Strong materials and clever design raise the cost, but they also make the clutch reliable under pressure. Prices often start near $700 and can reach $2,500 or higher, depending on brand and vehicle needs. The work to install one also adds up, since the process takes more skill and extra hours in the shop.

Labor costs are also elevated, as the installation process is more complex and time-consuming.

An OEM clutch lines up with the exact design of the original part in your car, so it gives you a smooth and reliable drive. These clutches also come at a lower price range, usually between $500 and $2,500. Another plus is the installation. Because the process is straightforward, mechanics charge less for labor compared to performance clutch setups.

The total replacement cost for an OEM clutch is a cost-effective solution for standard marine applications.

Maintenance costs of outboard parts can add up quickly. Choose higher-quality components up front to reduce downtime, repair bills, and frustration during your boating season.

Comparison Table - Performance vs OEM Clutch

| Factor | Performance Clutch | OEM Clutch |

| Torque Capacity | Higher, designed to handle increased torque for high-performance applications. | Standard; sufficient for typical marine engine outputs. |

| Heat Resistance | Enhanced; built to withstand higher temperatures, reducing the risk of overheating. | Standard; may overheat under high-stress conditions. |

| Weight | Often lighter; contributes to improved engine responsiveness. | Heavier may slightly reduce engine responsiveness. |

| Noise Levels | Higher may produce more noise due to aggressive engagement. | Lower; designed for quieter operation. |

| Maintenance Needs | Higher; may require more frequent maintenance due to increased wear. | Lower; designed for longevity with standard maintenance intervals. |

| Cost | Higher, due to advanced materials and design features. | Lower cost-effective for standard applications. |

FAQs

1. What is the best clutch for daily driving?

For daily driving, an OEM or mild-performance clutch offers smooth engagement, low pedal effort, and longevity. Brands like Exedy, ACT, and Clutch Masters provide reliable options.

2. When should I stick with an OEM clutch?

Stick with an OEM clutch if your vehicle remains stock, you prioritize comfort, and you don't plan on increasing power. OEM clutches offer reliability and cost-effectiveness for standard use.

3. Do performance clutches shift better under heavier load?

Yes, performance clutches are designed to handle higher torque, providing quicker and more precise shifts under heavy loads. They're ideal for spirited driving or track use.

4. How do I know when my clutch needs replacement?

Signs include slipping (engine RPM increases without acceleration), difficulty shifting gears, a spongy or soft clutch pedal, or unusual noises. If these occur, it's time to inspect or replace the clutch.

5. Can you replace an OEM clutch with a performance one on a stock boat?

Yes, but consider compatibility. Performance clutches may require modifications and could affect drivability. Ensure the upgrade aligns with your boat's power and usage requirements.

Conslusion

When picking between OEM and performance marine clutches, consider how you actually use your boat:

- Daily Leisure & Low-Stress Cruising: Stick with a standard OEM clutch. Its smooth engagement, reliable materials, and factory compatibility make it the hassle-free option that delivers when you just want to get on the water.

- Heavy Loads, Frequent Docking, Towing, or Upgraded Engines: Step up to a performance clutch. Designed to handle higher torque, resist heat, and maintain bite under increased demand, they give you confidence when the workload increases.

- Workboats, Tug Operations, Commercial Use: Opt for rugged, multi-disc or hydrodynamic performance designs built for extended cycles and high reliability.

To find quality marine parts, always buy from authorized dealers or trusted sources.

Shop OEM and performance marine clutches at OBParts or call us at 270-618-5200 for expert guidance on the right fit for your boat.

Posted by Brian Whiteside